TURNHOUSE AGI

A new AGI was constructed in the Turnhouse area due to the construction of a tram station for Edinburgh’s new electric tram system.

A new AGI was constructed in the Turnhouse area due to the construction of a tram station for Edinburgh’s new electric tram system.

Technica’s scope involved the procurement and installation of all instrumentation, software, telemetry, electrical switchgear and electrical equipment associated with a new AGI. The scope also entailed installing and commissioning equipment associated with a new boiler house and boiler house controls. Following installation completion the installation was then fully tested and commissioned by Technica. Throughout the project Technica managed commercial and technical issues associated with changes made during construction. Technica also represented our client Murphy Pipelines at the end user SGN’s monthly construction review meetings.

THE PROJECT SCOPE OF SUPPLY WAS GENERALLY:

> Equipment Procurement

> Installation of Cable Management, Surface Ducting and Tray

> Electrical Installation – New REC supply intake kiosk, 1:1 Transformer, Site Lighting and Exe/Exd Distribution Equipment

> Instrumentation Installation – Installation of new telemetry, Exi, Exe, Exd Instrumentation Equipment and Hookups

> Electrical Testing and Certification

> Impulse Pipework Installation and Testing

> Instrument Loop/Point to Point Checks

> Hazardous area inspections

> Telemetry End to End Tests

> Final Handover Documentation

Technica were chosen by SGN from their Design Framework as design partners for the St Mary Cray Turbo Expander Project.

Technica were chosen by SGN from their Design Framework as design partners for the St Mary Cray Turbo Expander Project.

Technica were appointed by Excelerate Energy to conduct the Front End Engineering Design (FEED), Onshore and Offshore designs for the development of the Aguirre Offshore GasPort® Project.

Technica were appointed by Excelerate Energy to conduct the Front End Engineering Design (FEED), Onshore and Offshore designs for the development of the Aguirre Offshore GasPort® Project.

Technica carried out the detail design services for several water and waste water treatment site upgrades.

Technica carried out the detail design services for several water and waste water treatment site upgrades.

The Immingham Renewable Fuels Terminal is the world’s largest dedicated biomass handling facility. The new facility uses continuous ship unloaders to offload wood pellets from vessels on to a

The Immingham Renewable Fuels Terminal is the world’s largest dedicated biomass handling facility. The new facility uses continuous ship unloaders to offload wood pellets from vessels on to a

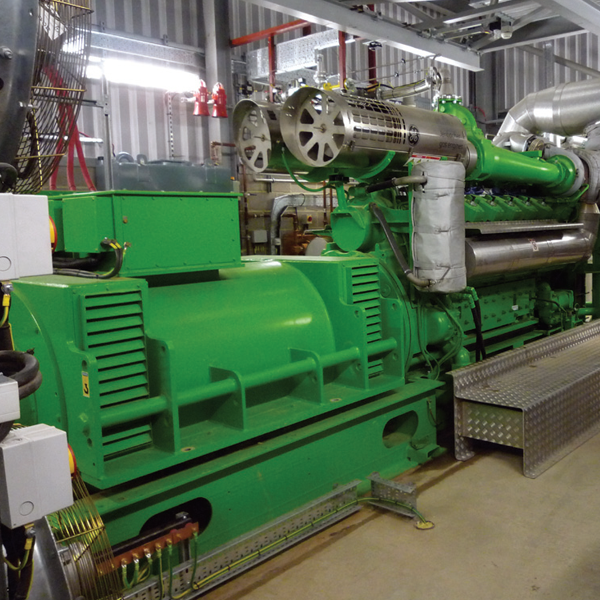

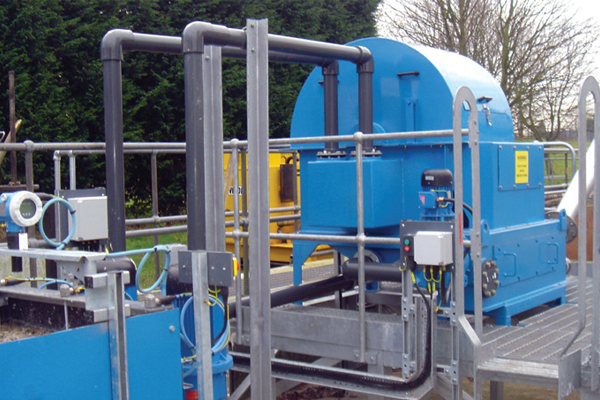

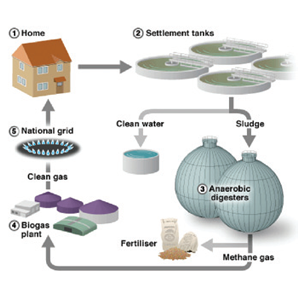

Biomethane can be produced via many industries such as farming, waste food, water and sewage. Many methane gas producers could see a real benefit from injecting gas as Biomethane into the UK Gas Network.

Biomethane can be produced via many industries such as farming, waste food, water and sewage. Many methane gas producers could see a real benefit from injecting gas as Biomethane into the UK Gas Network. Example of Existing Methane Gas Production from Waste Water

Example of Existing Methane Gas Production from Waste Water

Built to accommodate the proprietary technology of Excelerate Energy’s specialised Energy Bridge Regasification Vessel fleet, the GasPort project required less land-based infrastructure than conventional onshore terminals. As a result, the project took less than a year to design, permit and construct for £40 million; onetenth the cost of a traditional onshore terminal.

Built to accommodate the proprietary technology of Excelerate Energy’s specialised Energy Bridge Regasification Vessel fleet, the GasPort project required less land-based infrastructure than conventional onshore terminals. As a result, the project took less than a year to design, permit and construct for £40 million; onetenth the cost of a traditional onshore terminal.

GNL Escobar (GNLE) is Argentina’s second liquefied natural gas (LNG) receiving facility using Excelerate Energy’s Gasport where design and engineering support has been provided by Technica.

GNL Escobar (GNLE) is Argentina’s second liquefied natural gas (LNG) receiving facility using Excelerate Energy’s Gasport where design and engineering support has been provided by Technica.

Technica were appointed by Excelerate Energy to conduct the Front End Engineering Design (FEED) work for the development of the first floating gas liquefaction facility in the United States utilising its Floating Liquefaction Storage Offloading vessel (FLSO™) technology. The facility will be situated on the Texas Gulf Coast, and will be designed to export liquefied natural gas (LNG) to markets worldwide by 2017.

Technica were appointed by Excelerate Energy to conduct the Front End Engineering Design (FEED) work for the development of the first floating gas liquefaction facility in the United States utilising its Floating Liquefaction Storage Offloading vessel (FLSO™) technology. The facility will be situated on the Texas Gulf Coast, and will be designed to export liquefied natural gas (LNG) to markets worldwide by 2017.

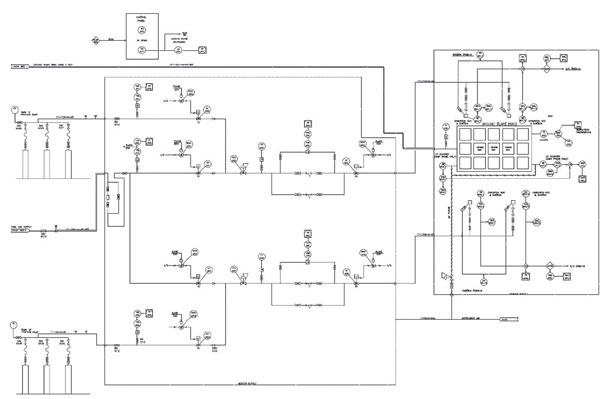

Technica were employed to provide mechanical and instrumentation survey services for the existing oil process plant. The site was surveyed and compared against legacy Piping and Instrumentation Drawings.

Technica were employed to provide mechanical and instrumentation survey services for the existing oil process plant. The site was surveyed and compared against legacy Piping and Instrumentation Drawings. The scope of the project consisted of:

The scope of the project consisted of: