Fiscal metering

Experts in custody transfer requirements, Technica will ensure your metering systems will meet the highest accuracy and traceability standards.

Technica specialise in tailoring flow metering solutions to meet the requirements of the client and stakeholders. Particular emphasis is placed on fiscal and custody transfer metering as well as allocation and environmental systems.

We design systems to comply with the relevant international measurement standards and guidelines, for example ISO, AGA, API, IP and OIML. Being independent from metering manufacturers allows us to select the most appropriate products to deliver a cost effective solution for optimum accuracy and performance.

We can produce procedures and work instructions for ongoing maintenance to ensure ongoing compliance to the relevant commercial agreements and international standards.

Our gas metering and analyser systems experience extends beyond pure fiscal metering. For example Technica’s Bio-methane to Grid kiosk includes a Flow Weighted Average Calorific Value measurement system and gas quality analysers to ensure the Gas Safety (Management) Regulations are met.

BIOMETHANE TO GRID (BtG)

Biomethane can be produced via many industries such as farming, waste food, water and sewage. Many methane gas producers could see a real benefit from injecting gas as Biomethane into the UK Gas Network. In many instances methane gas is already being produced by existing Anaerobic Digesters. Government backed incentives are now available to enable you to inject methane gas into the Gas Network over and above the UK wholesale gas price.

To drive down the capital costs and reduce lead time, Technica have developed a generic design for a fully integrated Network Entry Facility complete with OFGEM Approved Gas Chromatography Analysis, Pressure Reduction, Odorisation, Fiscal Metering, GS(M)R gas analysis and gas rejection.

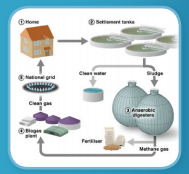

Example of Existing Methane Gas Production from Waste Water

Example of Existing Methane Gas Production from Waste Water

1. Domestic waste water heads to sewage processing plant

2. Settlement tanks separate sewage into clean water and sludge

3. Anaerobic digesters break down the waste and produce a thick, odourless waste and methane. By-product of waste solids are removed and sold for use as fuel or fertiliser.

4. Biogas plant cleans methane to remove impurities

5. Clean odorised biomethane injected into gas network

Technica’s BtG Solution

The design has been independently appraised by GL Noble Denton and is suitable for installation into any of the national gas network areas. The system provides filtration, slam shut valves and pressure reduction equipment to enable the pressure to be regulated to match the network entry point line pressure.

If biogas/biomethane production fails for any reason a shutdown valve and a non-return valve isolates the biogas plant from the gas network entry point main line gas pressure.

The Supervisory Control System monitors conditions of the biogas plant, together with gas quality and prevents gas that does not meet the requirements of GS(M)R entering the gas network. The fiscal metering system is a fully OFGEM approved solution ensuring the FWACV calculation meets the necessary network entry point agreement requirements.