Technica were chosen by SGN from their Design Framework as design partners for the St Mary Cray Turbo Expander Project.

Technica were chosen by SGN from their Design Framework as design partners for the St Mary Cray Turbo Expander Project.

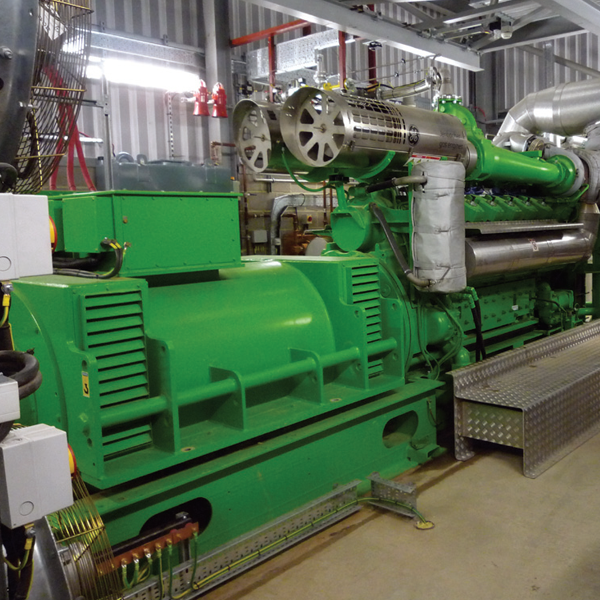

The project provides SGN with the option to generate electricity using the CHP and Turbo Expander which can be used as a pressure let down facility rather than via the inefficient traditional pressure reduction streams based on site. Technica provided multidiscipline design and engineering services associated with the installation of a new Atlas Copco two stage Turbo Expander (TE) , Combined Heat & Power (CHP) unit and Boiler package. The design of Process Gas system allowed the gas to be heated using gas/water heat exchangers.

The water system was designed to enable the water to be heated by reject heat from a new Combined Heat & Power (CHP) set coupled to a synchronous 4MW 11kV generator. This heating requirement was further augmented by a new medium pressure hot water boiler.

Technica were also responsible for the design, construction and implementation of the Plant Control System (PCS) which is central to the controls associated with the individual TE, CHP and Boiler control systems. Two new HV Switch rooms were designed allowing final connection to the EDF 11kV local distribution network.

TECHNICA PROVIDED A RANGE OF DESIGN AND ENGINEERING SERVICE ASSOCIATED WITH:

> Feasible Study

> Conceptual Design

> Detailed Design

> Equipment Specification

> HV Electrical Switchhear

> HV Electrical Network Analysis

> LV & HV Switch Room Civils

>LV Electrical System

>Control & Instrumentation

> SIL Assessments

> Functional Safety

> Process Gas System P&ID’s

> Water System P&ID’s

> Plant Control System Software

> Plant Control System Design, Build & Commission

> Third Part Vendor Management

> FAT Attendance

> Commissioning Support